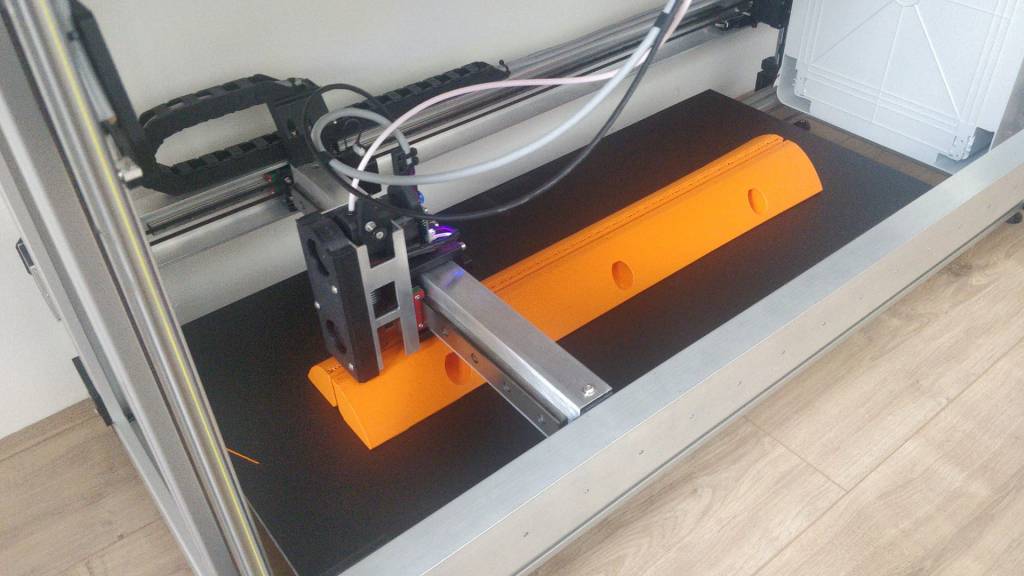

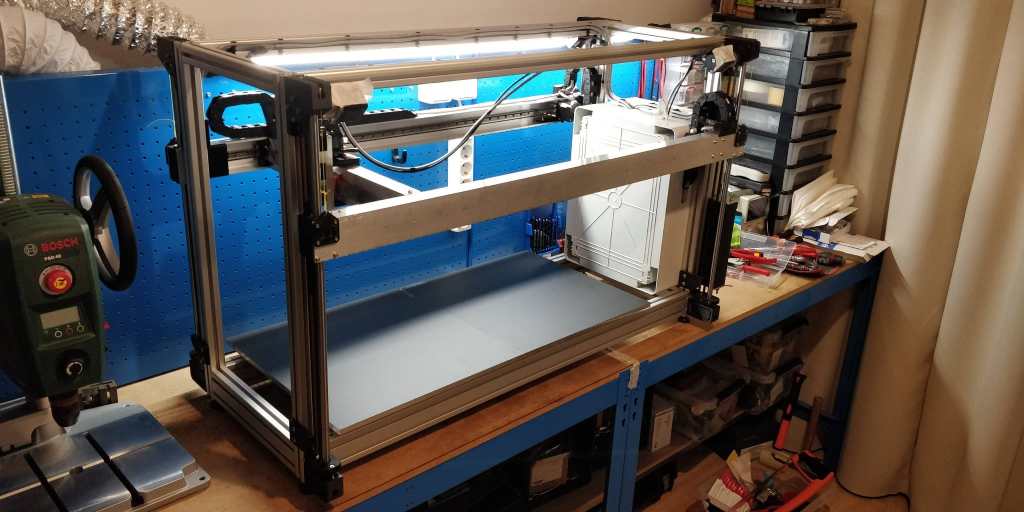

My new 3D printer design! Bigger and bolder then before! (or at least bigger). BigBoy has a sizeable build volume of 750x350x350 (l x b x h) and utilizes a moving gantry design. To keep the print times within reason a supervolcano hotend is used.

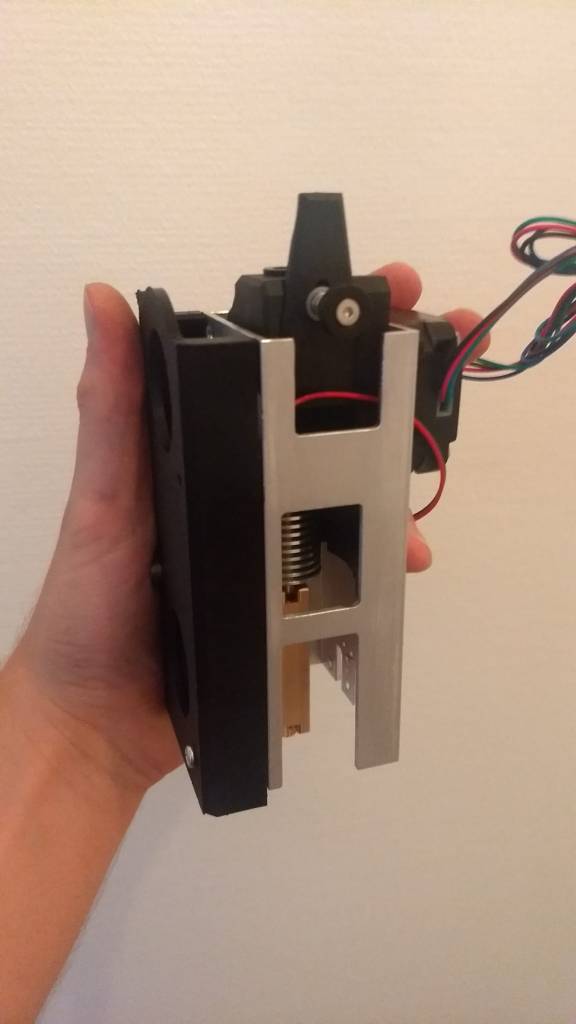

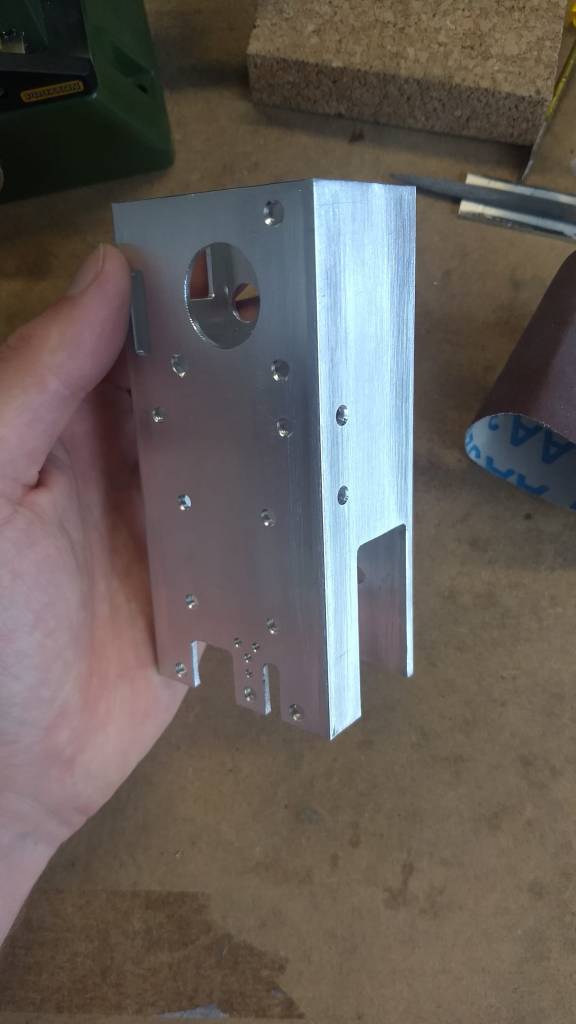

Bigboy’s frame is build from aluminium extrusion profiles.The XY motion is created with linear rails mounted in aluminium C-profiles, Z uses linear rods. All axes use belts for actuation, powered by 7 stepper motors. To control the in total 8 steppers the machine uses klipper firmware running on a raspberry pi and three controller boards. Two are in the electrical cabinet and one is on the printhead (connected to the RPI using CAN).

Here are some of the prints made by Bigboy: